- sales@completestudweld.com

- 216-904-4008

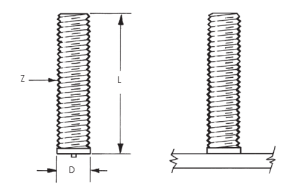

The Capacitor Discharge (CD) Stud Welding process is designed for welding CD type studs to sheet metal with little to no reverse side marking.

The ARC- Short Cycle process is also used to weld CD type studs to sheet metal and plate.

The smaller flange diameter allows for smaller diameter holes in components to be mounted on welded studs.

| A | B | C | D | E | F | G | |

|---|---|---|---|---|---|---|---|

|

1

|

Stud Specifications | Standard Accessories | |||||

|

2

|

Thread Size |

Stud Diameter |

Flange Diameter |

Min. Length | B Collet Standard 1-3/8” Long |

Long Collet 2 -3/8” Long |

Euro Collet 1.80” Long |

|

3

|

C | Z | D | L | P/N * | P/N ** | P/N |

|

4

|

M3 – .50 | 0.118 | 0.12 | 6mm | CDB-003M | CDBN-003M | CDBS-003M |

|

5

|

M4 – .70 | 0.158 | 0.16 | 6mm | CDB-004M | CDBN-004M | CDBS-004M |

|

6

|

M5 – .80 | 0.197 | 0.199 | 10mm | CDB-005M | CDBN-005M | CDBS-005M |

|

7

|

M6 – 1.00 | 0.236 | 0.238 | 10mm | CDB-006M | CDBN-006M | CDBS-006M |

|

8

|

M8 – 1.25 | 0.315 | 0.316 | 12mm | CDB-008M | CDBN-008M | CDBS-008M |

|

9

|

M10 – 1.50 | 0.394 | 0.395 | 12mm | CDB-010M | CDBN-010M | CDBS-010M |

|

10

|

* Note, requires B Stop, see Accessories for details | ||||||

|

11

|

** Note, Requires Long Style Stops, see Accessories for details | ||||||