- sales@completestudweld.com

- 216-904-4008

ARC WELD STUDS-Technical Details

Threaded & No Thread Weld Studs: Complete Stud Welding has various types of externally and

internally threaded weld studs and No Thread weld studs. These weld studs are used in many

industrial and construction applications.

Specifications: Complete Stud Welding studs are commonly produced to AWS Specifications D1.1,

D1.5 and or D1.6. Threaded weld studs and No Thread weld studs are available upon request to

various international specifications. Should Certifications be required, please request these as part of

the quotation details and at the time of order.

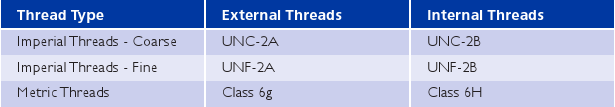

Threads: The chart below depicts the thread standards for imperial and metric external and internal

threads. Unless requested or quoted otherwise, threads will be quoted based on these common

thread standards.

Unless indicated or quoted otherwise, external threads will be a rolled type thread. The strength and

surface finish of rolled threads are considered to be superior to cut type threads.

Flux: All Standard Arc Welding Studs are flux loaded for diameters greater than 3/16”.

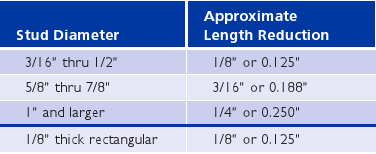

Length: The length dimension (L) indicated throughout these specifications is the overall length of

the stud Before Weld (BW). The After Weld (AW) length will be shorter based on the stud diameter as

depicted in the chart below:

Material: Low Carbon Steel weld studs are available in ASTM A108 / A29, Grade C1010 to C1020

material per AWS D1.1. In Stainless Steel, ASTM A-276 / A-493 Grades 302, 304, 310, 316, 321 are

options. Stainless threaded weld studs are mostly stocked in grade 302HQ / 30430.

Plating: All CSW ARC Weld Studs are supplied with a plain finish / unplated condition. Upon request,

CSW can provide Zinc Plating, Nickel Plating and Copper Plating. Zinc plated studs must be capped

on the weld end to preclude the plating from compromising the weld quality.

Annealing: Standard in stock product is not post annealed. Low carbon steel and stainless steel

studs can be annealed to a maximum of 75 Rockwell B hardness and 85 Rockwell B hardness,

respectively.

Ferrules: The standard ferrule shipped for each thread diameter is listed on the specification page

for each type of threaded weld stud. If other ferrules are desired, please specify at time of order. For

other ferrule options please see General Ferrule Specification or contact your CSW representative for

assistance.

Accessories: For required accessories, please see each specification page or contact your CSW

representative for assistance.

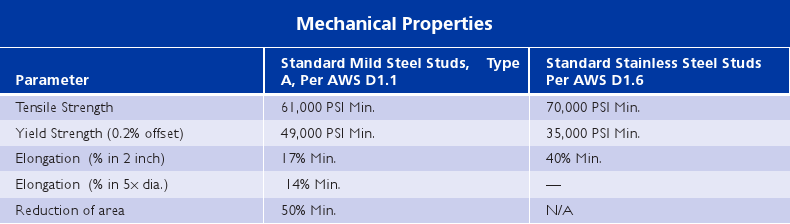

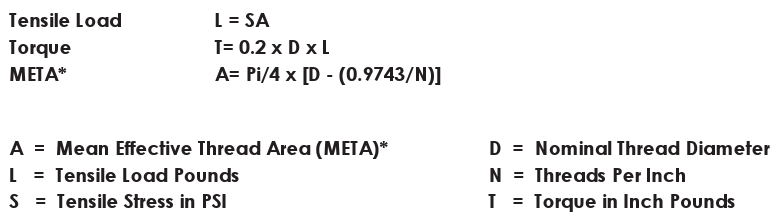

Tensile and Torque Strengths: The 2 charts – Standard ARC Welding Studs –

Tensile / Torque Strengths can be found under ARC Stud Welding – General Information.

The data was calculated based on the formulas shown below.

*META is used instead of root area in calculating screw strengths because of closer correlation with

actual tensile strength. META is based on mean diameter, which is the diameter of an imaginary

coaxial cylinder whose surface would pass through the thread profile approximately midway

between the minor and pitch diameters.

**Please note, in actual practice a stud should not be used at its yield load. A factor of safety must

be applied. It is generally recommended that studs be used at no more than 60% of yield. However

the factor of safety may vary up or down, depending on the application. The user will determine the

appropriate safety factor.

***Please note, Torque figures based on assumption that excessive deformation of thread has not

taken relationship between torque/tension out of its proportional range. All torque figures are shown

in foot pounds (ft lbs).

Shear values were calculated at 60% of the Ultimate Tensile Load of the stud.

WEIGHT CHART – Threaded Weld Studs

WEIGHT CHART – No Threaded Weld Studs