- sales@completestudweld.com

- 216-904-4008

Complete Stud Welding CTB weld studs are a superior option to securing cable tie bases compared to adhesives or screws.

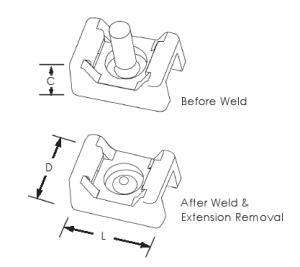

To install, first weld the wire tie base in place, then break off the top portion of stud and insert cable tie. Holds wire bundle up to 1 in diameter.

The retaining stud is a .188 diameter stainless steel or aluminum knock-off style CD stud.

The pull off strength of the cable tie base exceeds that of a typical 3/16 nylon wire tie.

For application, dimensional, in stock, technical details and welding assistance, please contact your Complete Stud Welding representative.

| A | B | C | D | E | F | G | H | |

|---|---|---|---|---|---|---|---|---|

|

1

|

Cable Tie Base Specifications | Standard Accessories | ||||||

|

2

|

Height | Length | Width | Slot Height | Slot Width | B Collet Standard 1-3/8” Long |

Long Collet 2-3/8” Long |

Euro Collet 1.80” Long |

|

3

|

C | L | D | A | W | P/N * | P/N ** | P/N |

|

4

|

0.39 | 0.875 | 0.625 | 0.09 | 0.325 | CDB-018 | CDBN-018 | CDBS-018 |

|

5

|

* Note, requires B Stop, see Accessories for details | |||||||

|

6

|

** Note, requires Long Style Stops, see Accessories for details | |||||||

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1

|

Nylon 6/6 Properties | ||||||||||||||||||

|

2

|

Property | ASTM Method | Test Condition | Units | Nylon 6/6 | ||||||||||||||

|

3

|

Tensile Strength | D368 | +73 Degrees F, 50% RH | kpsi | 11.2 | ||||||||||||||

|

4

|

Elongation at break | D368 | +73 Degrees F, 50% RH | % | > 299 | ||||||||||||||

|

5

|

Yield Strength | D368 | +73 Degrees F, 50% RH | kpsi | 8.5 | ||||||||||||||

|

6

|

Shear Strength | D732 | Dry as Molded | kpsi | 9.6 | ||||||||||||||

|

7

|

Deformation Under Load | D621 | 2,000 psi; +122 F, DAM | % | 1.4 | ||||||||||||||

|

8

|

IZOD Impact | D256 | +73 Degrees F, 50% RH | ft lb/in | 2.1 | ||||||||||||||

|

9

|

Tensile Impact Strength | D1822 | +73 Degrees F, Long Specimen; DAM |

ft lb/in | 240 | ||||||||||||||

|

10

|

Melting Point | D789 | Fisher-Johns | Degrees F | 491 | ||||||||||||||

|

11

|

Thermal Conductivity | — | DAM Conche-Fitch | BTU-in/h*ft*F | 1.7 | ||||||||||||||

|

12

|

Brittleness Temperature | D746 | 50% RH | Degrees F | -85 | ||||||||||||||

|

13

|

Oxygen Index | D2683 | DAM | %O | 28 | ||||||||||||||

|

14

|

Oxygen Index | D2683 | 50% RH | %O | 31 | ||||||||||||||

|

15

|

UL Flammability | UL 94 | DAM | — | V-2 | ||||||||||||||

|

16

|

UL Flammability | UL 95 | 50% RH | — | V-2 | ||||||||||||||

|

17

|

Nylon 6/6 NBS Smoke Generation | ||||||||||||||||||

|

18

|

Test Parameters | Specific Optical Density | |||||||||||||||||

|

19

|

Sample Thickness | UL Flammability | Energy Source | at Maximum Smoke Accumulation |

At 2 Minutes | ||||||||||||||

|

20

|

1/16 | 94 V-2 | Radiant (2.5 watts/sp cm) | 13 | 0 | ||||||||||||||

|

21

|

1/8 | 94 V-2 | Radiant (2.5 watts/sp cm) | 26 | 1 | ||||||||||||||

|

22

|

Nylon 6/6 Temperature Index | ||||||||||||||||||

|

23

|

Temperature Index | ||||||||||||||||||

|

24

|

Minimum Thickness | Electrical Degrees C | Mechanical w/o Impact Degrees C |

Hot Wire Ignition (sec) | |||||||||||||||

|

25

|

0.028 | 125 | 65 | 11.8 | |||||||||||||||

|

26

|

0.058 | 125 | 85 | 15 | |||||||||||||||

|

27

|

Weld Stud Dimensions and Properties | ||||||||||||||||||

|

28

|

Stud Diameter | Flange Diameter | Length | Length after knock-off * | Material Type ** | Ultimate Tensile | |||||||||||||

|

29

|

0.19 | 0.265 | 0.78 | 0.18 | 302 SS | 85 KPSI | |||||||||||||

|

30

|

* Excludes flange thickness | ||||||||||||||||||

|

31

|

** Along with 304 SS, meets requirements of 18-8 Stainless Steel | ||||||||||||||||||

Product Images