- sales@completestudweld.com

- 216-904-4008

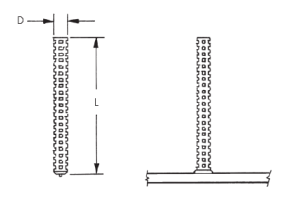

Deformed Bar Anchors are designed for weld and bearing plates in concrete connections.

Specifications – DBA’s meet AWS Specifications D1.1.

Material – Low carbon steel, ASTM A496

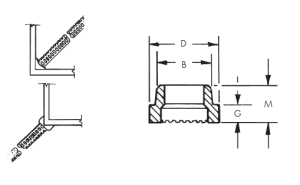

Ferrules – Flat ferrules are provided. For welding to the inside angle and outside angle refer to the next page for ferrule options.

Length – Lengths are listed before welding. For Stud Diameters (D) 1/2” and smaller the length reduction is roughly 1/8” and for (D) 5/8” and 3/4” the reduction is roughly 3/16”. DBA’s can be made in any length above the standard minimum.

Accessories – For a complete list of accessories required with each ferrule type, please see next page.

| A | B | C | D | E | F | G | H | |

|---|---|---|---|---|---|---|---|---|

|

1

|

Stud Specifications | Std. Acc. | ||||||

|

2

|

D | L | No. | D | B | G | M | |

|

3

|

3/8 | See subsequent page for standard lengths by DBA diameter. |

F037-F | .640 | .505 | .234 | .390 | |

|

3

|

1/2 | F050-F | .795 | .650 | .250 | .438 | ||

|

3

|

5/8 | F062-F | .1.030 | .785 | .328 | .469 | ||

|

3

|

3/4 | F062-F | 1.218 | 1.030 | .469 | .656 | ||

|

1

|

Mechanical Property Requirements | |

|---|---|---|

|

2

|

Type C | |

|

3

|

Tensile Strength | 80,000 psi min. (552 MPa) |

|

3

|

Yield Strength (0.5% offset) | 70,000 psi min. (485 MPa) |

|

3

|

Type C Studs are cold-worked deformed steel bars manufactured in accordance with specification ASTM A496 having a nominal diameter equivalent to the diameter of a plain wire; having the same weight per foot as the deformed wire. ASTM A496 specifies a maximum diameter of 0.628 in. (16mm). Any bar supplied above that diameter must have the same physical characteristics regarding deformations as required by ASTM A496. |

|

| A | B | C | D | E | F | G | |

|---|---|---|---|---|---|---|---|

|

1

|

Deformed Bar Anchor – Accessory Detail | ||||||

|

2

|

Stud Diameter | Chuck P/N | Ferrule Type | Ferrule P/N | Foot P/N | Grip P/N | Ferrule Foot Plate P/N (Dual Leg) |

|

3

|

1/4 | CN-025 | Flat | F025-F | B-1C | GC-025 | QN-025 |

|

4

|

Low Profile | F025-LP | B-1C | GC-025 | QN-025 | ||

|

5

|

Heavy Duty | F025-HD | B-1C | GC-037 | QN-037 | ||

|

6

|

Inside Angle | F025-IA | B-1C | GD-025 | N/A | ||

|

7

|

Outside Angle | F025-OA | B-1C | GC-025 | QN-025 | ||

|

8

|

3/8 | CN-037 | Flat | F037-F | B-1C | GC-037 | QN-037 |

|

9

|

Low Profile | F037-LP | B-1C | GC-037 | QN-037 | ||

|

10

|

Heavy Duty | F037-HD | B-1C | GC-050 | QN-050 | ||

|

11

|

Inside Angle | F037-IA | B-1C | GD-037 | N/A | ||

|

12

|

Outside Angle | F037-OA | B-1C | GC-037 | QN-037 | ||

|

13

|

1/2 | CN-050 | Flat | F050-F | B-1C | GC-050 | QN-050 |

|

14

|

Low Profile | F050-LP | B-1C | GC-050 | QN-050 | ||

|

15

|

Vertical | F050-V | B-1C | GC-050 | QN-050 | ||

|

16

|

Heavy Duty | F050-HD | B-2C | GC-062 | QN-062 | ||

|

17

|

Inside Angle | F050-IA25 | B-1C | GD-050 | N/A | ||

|

18

|

Inside Angle | F050-IA37 | B-1C | GD-050 | N/A | ||

|

19

|

Outside Angle | F050-OA | B-1C | GC-050 | QN-050 | ||

|

20

|

5/8 | CN-062 | Flat | F062-F | B-2C | GC-062 | QN-062 |

|

21

|

Low Profile | F062-LP | B-2C | GC-062 | QN-062 | ||

|

22

|

Vertical | F062-V | B-2C | GC-062 | QN-062 | ||

|

23

|

Heavy Duty | F062-HD | B-2C | GC-075 | QN-075 | ||

|

24

|

Inside Angle | F062-IA25 | B-2C | GD-062 | N/A | ||

|

25

|

Inside Angle | F062-IA37 | B-2C | GD-062 | N/A | ||

|

26

|

Outside Angle | F062-OA | B-2C | GC-062 | QN-062 | ||

|

27

|

3/4 | CN-075 | Flat | F075-F | B-2C | GC-075 | QN-075 |

|

28

|

Low Profile | F075-LP | B-2C | GC-075 | QN-075 | ||

|

29

|

Vertical | F075-V | B-2C | GC-075 | QN-075 | ||

|

30

|

Inside Angle | F075-IA37 | B-2C | GD-075 | N/A | ||

|

31

|

Inside Angle | F075-IA50 | B-2C | GD-075 | N/A | ||

|

32

|

Outside Angle | F075-OA | B-2C | GC-075 | QN-075 | ||

Deformed Bar Anchor – Standard Sizes

| A | B | C | D | E | F | G | H | I | |

|---|---|---|---|---|---|---|---|---|---|

|

1

|

Specifications | Packaging Detail | Weights – in pounds | ||||||

|

2

|

Diameter | Length | CSW Part Number (mild steel) |

Pieces Per Box |

Boxes Per Pallet |

Pieces Per Pallet |

Box Weight | Pallet Weight |

1,000 Pcs. Weight |

|

3

|

D | L | |||||||

|

4

|

3/8 | 10 – 1/8 | DBA0371012 | 150 | 18 | 2,700 | 46 | 828 | 307 |

|

5

|

12 – 1/8 | DBA0371212 | 150 | 18 | 2,700 | 55 | 990 | 367 | |

|

6

|

18 – 1/8 | DBA0371812 | 150 | 12 | 1,800 | 80 | 960 | 533 | |

|

7

|

24 – 1/8 | DBA0372412 | 150 | 8 | 1,200 | 108 | 864 | 720 | |

|

8

|

30 – 1/8 | DBA0373012 | 150 | 7 | 1,050 | 130 | 910 | 867 | |

|

9

|

36 – 1/8 | DBA0373612 | 150 | 6 | 900 | 156 | 936 | 1,040 | |

|

10

|

48 – 1/8 | DBA0374812 | 150 | 6 | 900 | 208 | 1,248 | 1,387 | |

|

11

|

1/2 | 8 – 1/8 | DBA0500812 | 100 | 18 | 1,800 | 44 | 792 | 440 |

|

12

|

10 – 1/8 | DBA0501012 | 100 | 18 | 1,800 | 54 | 972 | 540 | |

|

13

|

12 – 1/8 | DBA0501212 | 100 | 18 | 1,800 | 67 | 1,206 | 670 | |

|

14

|

18 – 1/8 | DBA0501812 | 100 | 12 | 1,200 | 98 | 1,176 | 980 | |

|

15

|

24 – 1/8 | DBA0502412 | 100 | 8 | 800 | 128 | 1,024 | 1,280 | |

|

16

|

30 – 1/8 | DBA0503012 | 100 | 7 | 700 | 160 | 1,120 | 1,600 | |

|

17

|

36 – 1/8 | DBA0503612 | 100 | 6 | 600 | 192 | 1,152 | 1,920 | |

|

18

|

42 – 1/8 | DBA0504212 | 100 | 6 | 600 | 222 | 1,332 | 2,220 | |

|

19

|

48 – 1/8 | DBA0504812 | 100 | 6 | 600 | 256 | 1,536 | 2,560 | |

|

20

|

60 – 1/8 | DBA0506012 | 100 | 1 | 100 | 314 | 314 | 3,140 | |

|

21

|

5/8 | 12 – 3/16 | DBA0621218 | 50 | 18 | 900 | 51 | 918 | 1,020 |

|

22

|

18 – 3/16 | DBA0621818 | 50 | 12 | 600 | 76 | 912 | 1,520 | |

|

23

|

24 – 3/16 | DBA0622418 | 50 | 8 | 400 | 102 | 816 | 2,040 | |

|

24

|

30 – 3/16 | DBA0623018 | 50 | 7 | 350 | 126 | 882 | 2,520 | |

|

25

|

36 – 3/16 | DBA0623618 | 50 | 6 | 300 | 151 | 906 | 3,020 | |

|

26

|

42 – 3/16 | DBA0624218 | 50 | 8 | 400 | 176 | 1,408 | 3,520 | |

|

27

|

48 – 3/16 | DBA0624818 | 50 | 6 | 300 | 197 | 1,182 | 3,940 | |

|

28

|

3/4 | 12 – 3/16 | DBA0751218 | 40 | 18 | 720 | 60 | 1,080 | 1,500 |

|

29

|

18 – 3/16 | DBA0751818 | 40 | 12 | 480 | 87 | 1,044 | 2,175 | |

|

30

|

24 – 3/16 | DBA0752418 | 40 | 8 | 320 | 115 | 920 | 2,875 | |

|

31

|

30 – 3/16 | DBA0753018 | 40 | 6 | 240 | 142 | 852 | 3,550 | |

|

32

|

36 – 3/16 | DBA0753618 | 40 | 6 | 240 | 175 | 1,050 | 4,375 | |

|

33

|

42 – 3/16 | DBA0754218 | 40 | 6 | 240 | 205 | 1,230 | 5,125 | |

|

34

|

48 – 3/16 | DBA0754818 | 40 | 6 | 240 | 226 | 1,356 | 5,650 | |

|

35

|

For non standard sizes contact you Complete Stud Welding Representative. | ||||||||

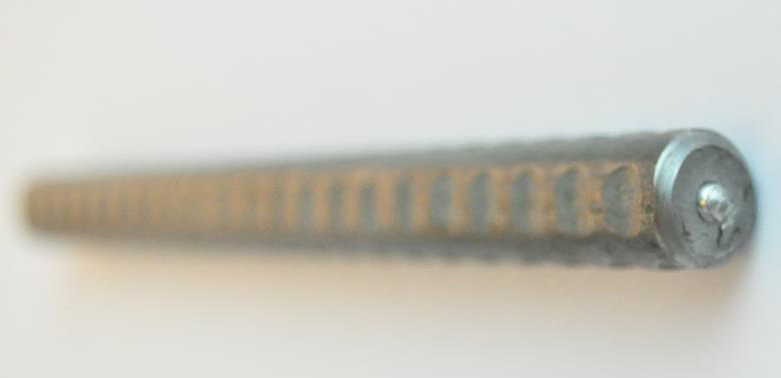

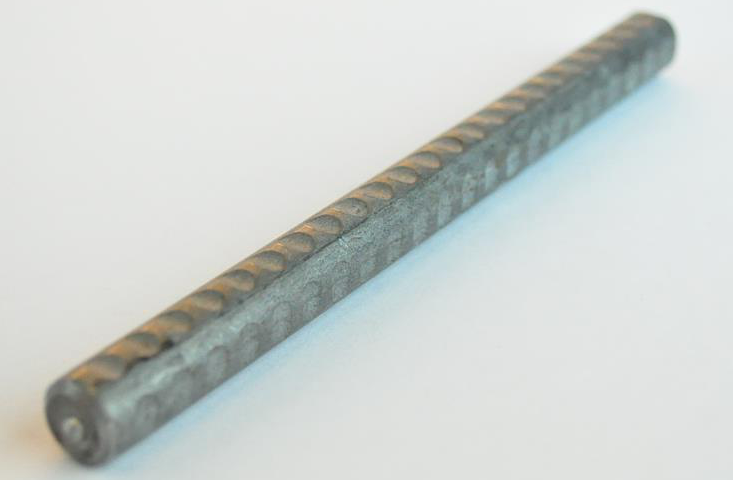

Product Images

For assistance in determining the best stud welding equipment options to meet the current and potential applications of your business, please contact us!

Arc Stud Welding is generally used to weld large diameter fasteners to rougher and thicker base metals. Arc studs may be almost any shape and there are literally hundreds; however, they must have one end of the fastener designed for arc welding.

Arc Stud Welding is a split second, one sided, no hole process producing a weld stronger than the base material and the stud itself.

Complete Stud Welding is engaged in the sales, rental, and support of stud welding products.

Our products include a full line of weld studs, standard and custom accessories, and a comprehensive line of stud welding equipment for rent and purchase.

We support our customers’ by; providing and answering technical questions; providing in shop process support, training, and troubleshooting; supplying equipment parts; and performing equipment repairs.