Choosing between short cycle weld studs vs arc weld studs is not always simple. The wrong decision can lead to warped metal, weak welds, extra rework, and production delays. The right decision saves money and protects the structure of the part.

While both methods fall under the “drawn arc” family, they serve very different masters. One is built for speed and thin materials. The other is designed for heavy lifting and maximum penetration. If you pick the wrong one, you might end up with warped metal or a weld that snaps under pressure.

Let’s break the comparison down in a way that is practical, technical, and easy to use on the shop floor.

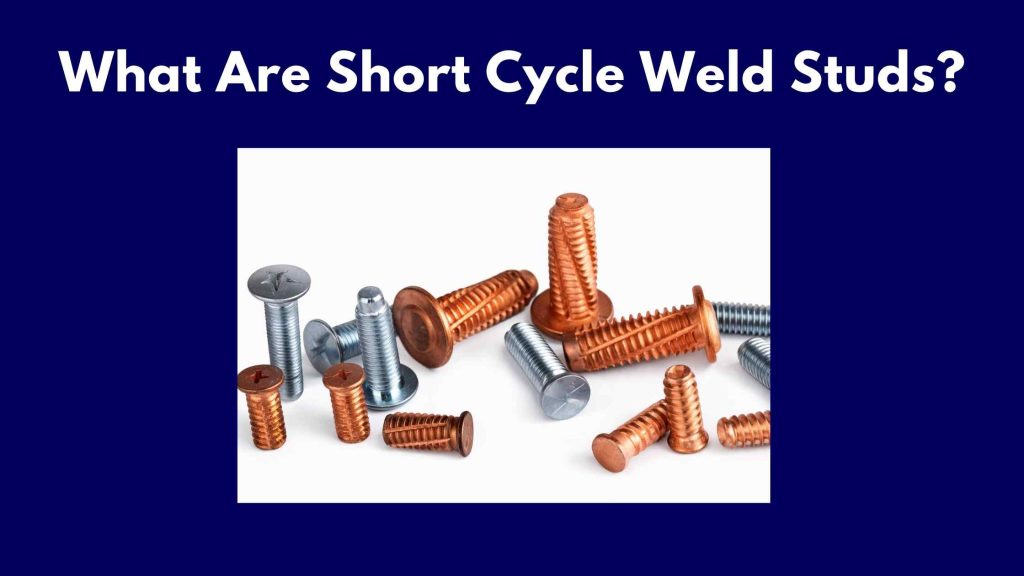

What Are Short Cycle Weld Studs?

The short-cycle stud welding process is essentially a faster version of the standard arc method. It usually takes place in under 100 milliseconds. Because the weld time is so brief, it creates a shallow “heat-affected zone.” This makes it perfect for thin-gauge materials where you want to avoid burning through the back of the sheet.

Short-cycle stud welding avoids ceramic ferrules. That means faster setup and fewer consumables. It works well across:

- Light sheet metal fabrication

- HVAC components

- Automotive panels

- Appliance assemblies

It is also widely used in production environments that need consistent welds at high speed.

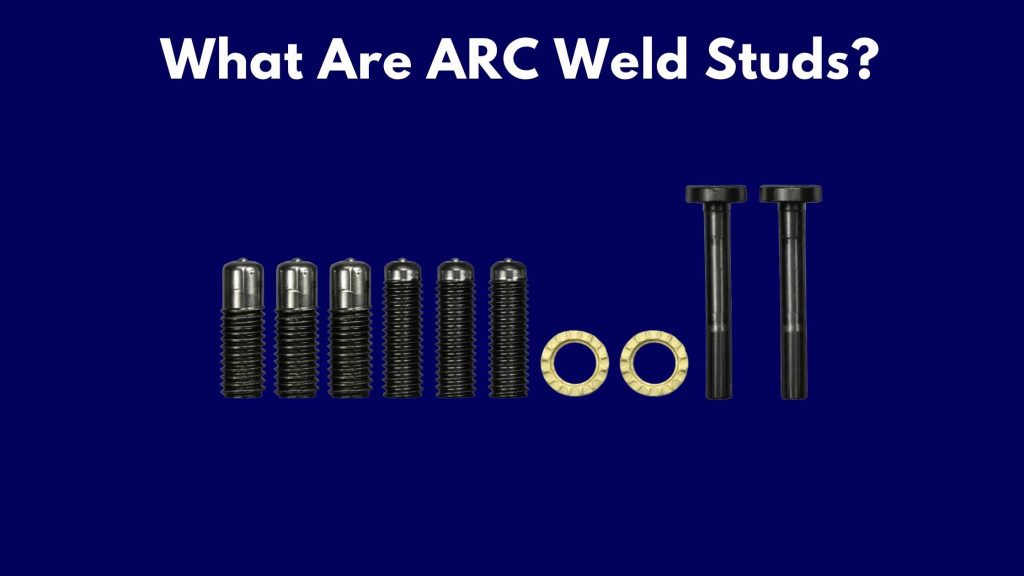

What Are ARC Weld Studs?

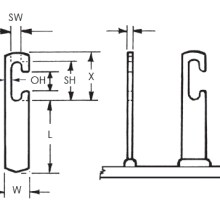

ARC weld studs (also called drawn arc studs) use sustained electrical current to create a longer, more controlled arc. The arc lifts the stud slightly off the base material, creating a pool of molten metal that fuses the stud permanently to the plate.

Weld time typically ranges from 2 to 10 seconds, depending on stud diameter and material thickness. You’re not fighting against time here. You’re building a stronger thermal bond.

These studs handle thicker materials, deeper penetration requirements, and applications demanding maximum tensile strength. Heavy-duty construction, shipbuilding, and structural steel work depend on this method.

Short Cycle Weld Studs vs ARC Weld Studs: Comparison

The differences become clearer when you look at the specifics.

| Factor | Short Cycle Weld Studs | ARC Weld Studs |

| Weld process | Short-cycle stud welding | Drawn arc stud welding |

| Weld time | 10–100 ms | Longer weld duration |

| Heat input | Lower | Higher |

| Material thickness | Thin sheets | Medium to thick plates |

| Ferrules required | No | Often yes |

| Typical studs | Small to medium | Medium to large |

| Risk of distortion | Low | Higher on thin metal |

| Strength penetration | Moderate | Deep, structural |

| Ideal environment | High-volume production | Heavy fabrication |

Where Short Cycle Weld Studs Perform Best

Short cycle weld studs are ideal when speed, appearance, and thin material protection are priorities.

Common use cases

- Inner automotive panels

- Electrical panel brackets

- Light frames and supports

- HVAC sheet metal

- Insulated appliance components

A report on stud welding systems shows continued growth in automated and faster welding solutions driven by thin-metal manufacturing. The automation segment of stud welding equipment has seen steady adoption increases over the last decade, particularly in automotive assembly.

Shops appreciate that short-cycle stud welding can be automated while keeping surfaces clean and stable.

Where ARC Weld Studs Lead

ARC weld studs are built for rugged jobs.

Best applications

- Construction projects

- Shipbuilding

- Structural steel

- Heavy equipment frames

- Industrial platforms and beams

Arc weld studs provide strong mechanical bonding. Penetration depth is greater, which is critical in safety-critical assemblies.

According to market research, stud welding demand in construction remains strong because large structural projects rely on stud-based fastening for load stability.

When longevity and load support matter more than cycle time, arc stud welding is often the safer choice.

Technical Considerations Before You Decide

Here’s how our team at Complete Stud Welding usually approaches it.

1. Base Metal Thickness

- Thin sheet metal

- Choose short-cycle stud welding.

- Thick plate or structural steel

- Choose drawn arc stud welding.

2. Weld Strength Requirements

If the stud must carry structural load, arc weld studs generally win due to deeper fusion.

3. Heat Sensitivity

Thin metal can warp with heat. Short-cycle stud welding minimizes distortion.

4. Production Speed

Short cycle systems complete welds faster and often integrate into automated lines.

5. Appearance Needs

Short cycle welds produce cleaner reverse sides, often needing little finishing.

Specifications

| Criteria | Short-Cycle Stud Welding | Arc Stud Welding Process |

| Typical stud size | Small to mid-range | Medium to large |

| Backside marking | Minimal | Possible |

| Consumables | None or limited | Ferrules or shielding |

| Operator skill | Moderate | Moderate to advanced |

| Automation fit | Excellent | Good but slower |

These details help explain why arc stud welder equipment is common on construction sites, while short cycle weld studs dominate controlled production environments.

Cost Analysis

Equipment cost is one variable. Total cost of ownership is different.

Short cycle systems run $15,000 to $40,000 depending on features and capacity. Operating costs are relatively low. Fast cycle times mean lower labor cost per stud. Minimal spatter means less cleanup.

Arc welding equipment costs $20,000 to $80,000. Longer process times add labor overhead. Spatter cleanup requires more attention. But here’s the offset. In applications where you need arc welding, you simply cannot use a short cycle without sacrificing quality. The cost difference becomes irrelevant when your only option is arc.

Many manufacturers run both. High-volume, thin-material work flows through short cycle lines. Critical structural components go through arc welding. You’re matching the process to the requirement, not forcing one method everywhere.

Making Your Choice

Ask yourself three questions:

One. What is the base material thickness? Thin sheet metal (under 3 mm) tips toward a short cycle. Thick material (over 5 mm) demands arc welding.

Two. What is your production volume? High volume, repetitive work favors short cycle efficiency. Lower volume, diverse jobs may justify arc welding flexibility.

Three. What are your strength requirements? Aesthetic studs on non-structural components can be short cycles. Load-bearing connections need arc welding.

Get Expert Guidance Today

Navigating the world of stud arc welding can be confusing if you are doing it alone. One wrong setting can lead to a lot of wasted material and time. We have spent years perfecting the art of the bond, and we want to help you do the same.

If you are unsure whether short cycle weld studs are right for your specific application, give us a call. Our team can look at your specs and give you a straight answer. We stock a massive inventory of both styles, ensuring you get exactly what you need without the long wait.

Contact Complete Stud Welding today. Let’s get your project started with the right equipment and the right studs. Call us at 216-904-4008

Comments are closed.