Arc Stud Welding has revolutionized how industries approach heavy-duty fastening challenges. Whether you’re constructing a steel skyscraper, building heavy equipment, or securing components in demanding marine environments, understanding Arc Stud Welding is critical to project success and cost efficiency.

This comprehensive guide explores everything you need to know about arc weld studs—from technical specifications to real-world applications—so you can make informed decisions about your fastening strategy.

What Are ARC Weld Studs?

ARC weld studs are specialized fasteners permanently attached to base metals through Stud Arc Welding technology. Unlike traditional bolts requiring pre-drilled holes, these studs create one-sided, no-hole welded connections stronger than both the base material and the stud itself.

The Stud Arc Welding process is remarkably efficient: an electric arc strikes between the stud and base metal, melting both surfaces in 0.1-0.5 seconds. The stud then plunges into the molten pool, creating a metallurgical bond. This single-sided access requirement makes arc stud welding ideal when drilling through materials is impractical or structurally undesirable.

Core Types of ARC Weld Studs

The diversity within the ARC weld studs category reflects the varied demands of modern manufacturing and construction. Understanding each type helps you select the right fastener for your specific application.

Headed Concrete Anchors

Headed concrete anchors represent one of the most widely used variants of ARC weld studs. These fasteners feature a distinctive hemispherical or flat head that provides mechanical interlock with concrete surfaces. When welded to structural steel that’s subsequently embedded in concrete, these Stud Arc Welding anchors create exceptional pull-out resistance.

The engineering behind headed concrete anchors is particularly sophisticated. The head diameter (typically 1.5 to 2 times the stud diameter) distributes loads across a wider concrete surface, significantly increasing overall joint strength. Industries ranging from bridge construction to parking structure development rely heavily on these components.

Headed Shear Connectors

Shear connectors serve a fundamentally different purpose than their concrete-anchoring cousins. These ARC weld studs are engineered specifically to transfer horizontal and vertical shear forces between two materials—most commonly between structural steel and reinforced concrete decking.

In composite steel-concrete construction, shear connectors are absolutely essential. They prevent relative movement between the steel beam and concrete slab, allowing both materials to work together as a unified structural system. This composite action increases load-carrying capacity by 30-40% compared to unreinforced systems, which is why modern bridge engineering and high-rise construction depend critically on proper shear connector specification.

Deformed Bar Anchors

Deformed bar anchors incorporate longitudinal ribs or deformations along their body, which dramatically enhance mechanical bonding with concrete. These deformations are not cosmetic—they create a mechanical interlock that increases anchorage strength compared to plain-surface studs.

The deformation pattern serves multiple purposes: it increases surface area, creates mechanical resistance to pullout, and improves load distribution within the concrete matrix. For applications requiring maximum concrete anchorage in challenging conditions, deformed bar anchors often become the engineer’s choice.

Punching Shear Resistors (PSR)

Punching shear resistors address one of the most critical failure modes in concrete-steel composite systems: punching shear around concentrated column loads. As column loads transfer through steel decking into concrete, stress concentrations can develop around the attachment point.

PSR studs are specifically designed with geometry that creates additional load-spreading capability, preventing localized concrete crushing. These specialized ARC weld studs have become increasingly important in flat-plate construction and parking structures where column loads concentrate significant force through relatively small areas.

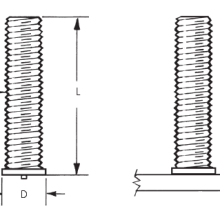

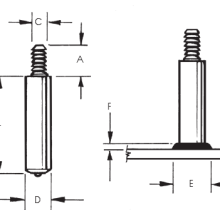

Threaded Fastener Variants

ARC weld studs extend beyond simple headed designs. Threaded fully welded studs, partially threaded options, knock-off variants, and collar-threaded designs provide versatility for applications requiring post-weld threading, specific anchor lengths, or unique installation requirements. Each variant addresses particular engineering constraints.

Key Applications Where ARC Weld Studs Excel

Structural Steel and Bridge Engineering

ARC weld studs help transfer loads between concrete decks and steel beams, enabling lighter and more efficient composite bridge designs. When specified correctly, shear connectors can reduce steel usage by up to 25%.

Parking Structures and Multi-Story Buildings

Studs provide essential shear resistance in parking decks and high-rises, helping manage concentrated loads. Since Stud Arc Welding doesn’t require backside access, construction becomes faster and more economical.

Heavy Equipment Manufacturing

Manufacturers rely on ARC studs for mounting components, creating lift points, and adding reinforcement. Their high-strength joints often allow designers to reduce material thickness and overall weight.

Petrochemical and Offshore Structures

ARC-welded anchors offer strong, corrosion-resistant connections needed in marine and subsea environments. They are widely used for platforms, underwater equipment, and structural anchoring.

Automotive and Transportation

Although CD studs dominate automotive production, ARC studs are used in heavy-duty vehicles and trailers where structural reinforcement and high-load attachment points are required.

Material Specifications and Strength Characteristics

ARC weld studs are available in multiple materials chosen for strength, durability, and environmental performance.

Carbon Steel Studs

The most widely used option, carbon steel studs (ASTM A354 Grade BD / A108), offers strong performance at low cost, delivering tensile strengths of roughly 80,000–120,000 PSI for general construction and industrial use.

Alloy Steel Variants

Alloy steels with elements like molybdenum, chromium, or nickel provide higher strength and corrosion resistance, making them ideal for extreme temperatures or harsher operating conditions.

Stainless Steel and Duplex Options

Stainless steel studs ensure excellent corrosion resistance for marine, chemical, and food applications. Duplex stainless options deliver even higher strength, though at significantly higher material costs.

Benefits of Arc Stud Welding

When compared to mechanical fastening, the Arc Stud Welding process offers performance gains that directly impact efficiency and reliability.

Superior Joint Strength

Arc welds create true metallurgical fusion, producing joints stronger than the stud or base metal. Failures typically occur in the surrounding material—not the weld.

One-Sided Access Requirement

Arc Stud Welding needs access to only one surface, eliminating the design and assembly limitations of through-bolting.

Eliminating Hole-Drilling Re

The absence of drilled holes and the strength of fused joints provide exceptional fatigue resistance in repetitive load conditions.

Rapid Installation

The Arc Stud Welding process completes in milliseconds, enabling fast, large-scale installation—especially beneficial on projects requiring hundreds of attachment points.

Selecting the Right ARC Weld Studs for Your Project

Choosing the correct stud involves evaluating load requirements, material compatibility, environment, and equipment capabilities.

Load Type and Magnitude Assessment

Identify whether your application involves static, dynamic, or impact loads. This determines material grade and stud diameter. For concrete anchorage, define whether forces are tension, shear, or a combination—most real-world cases involve combined loading.

Base Metal Compatibility

Carbon steels weld easily, while high-strength steels, stainless steels, and aluminum may require special procedures or different stud materials. Thicker base metals are easier to weld; materials thinner than about 3/16 inch may be better suited to short-cycle or CD stud welding.

Environmental Considerations

Weather can directly affect weld quality. Cold, rain, and wind often require controlled setups. If the structure will face corrosive conditions—marine, chemical, or industrial—select stainless or duplex studs for long-term durability.

Installation Equipment Specifications

Ensure your Stud Arc Welding equipment matches the required stud size and material. Equipment that’s too weak produces poor welds, while oversized units can overheat thin materials. Proper power control is key to consistent weld quality.

Conclusion

Selecting proper arc weld studs requires technical expertise, balancing load requirements, material compatibility, and cost efficiency. Complete Stud Welding’s technical team guides customers through these complex decisions, ensuring optimal fastener specification and installation procedures.

Contact our experts at 216-904-4008 or sales@completestudweld.com to discuss your specific project requirements. We’ll help you select the exact ARC weld studs and supporting equipment to deliver superior results on schedule and within budget.

For complex projects requiring on-site support, equipment rental, and installation assistance, we deliver comprehensive solutions that transform fastening strategy into a competitive advantage.

Comments are closed.