Finding a way to attach fasteners to thin metal without leaving ugly marks is a common challenge. Traditional welding often creates too much heat. This leads to warping or discoloration on the reverse side of the metal.

At Complete Stud Welding, we recommend CD weld studs for these specific situations. This process creates a strong bond in a fraction of a second. It is the cleanest way to handle thin-gauge materials.

In this article, we break down real-world uses, expert guidance, and solid data so you can understand how CD weld studs support strong builds and efficient production. But before we begin, if you want tailored support or product advice, call us at 216-904-4008.

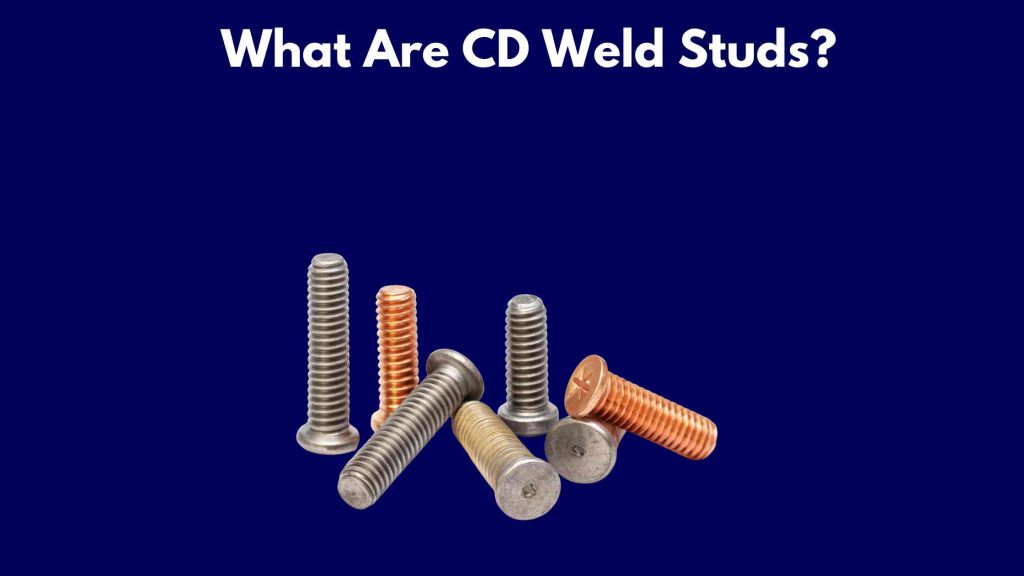

What Are CD Weld Studs?

A CD weld stud is a fastener that gets attached to metal surfaces using a specific welding technique. CD stands for capacitor discharge. The name describes exactly how the stud welding process works. An electrical charge builds up in a capacitor. When released, it creates the heat needed to bond the stud to the base metal.

Unlike traditional bolts that require pre-drilled holes, CD weld studs don’t need that preparation. You apply them directly to the surface. This saves time. It saves money. It eliminates the weakness that pre-drilled holes can create.

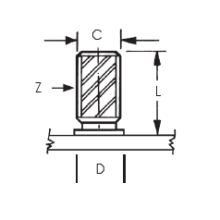

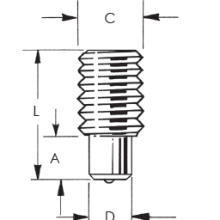

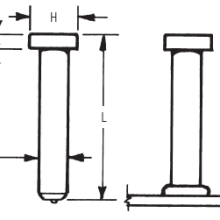

The stud itself is a short metal pin with a specially designed contact point. When the CD stud welder applies power, that contact point melts into the base metal. The stud bonds permanently. Within seconds, you have a secure connection ready for fastening.

How Does CD Stud Welding Work?

The CD stud welding process sounds complicated, but it follows simple principles.

Positioning and Setup

The process starts with positioning. You hold the stud against the metal surface where it needs to bond. A special CD stud welder tool creates the electrical connection. The operator triggers the release.

The Discharge and Fusion

Electrical energy stored in a capacitor discharges in milliseconds. This creates extreme heat at the contact point between the stud and the base metal. The base metal melts slightly. The stud sinks into this molten material. As everything cools, a permanent bond forms.

Speed and Alignment

The entire process takes less than a second. Speed matters because the stud stays in perfect alignment. There’s no time for drift or misalignment. This rapid execution means consistent results every time.

Localized Heat Control

The heat involved is localized. Only the immediate contact area reaches the melting temperature. The surrounding metal barely gets warm. This protects nearby components and finishes. The controlled heat zone prevents damage to sensitive equipment or coatings.

Matching Specifications to Applications

Different CD weld stud specifications exist for different applications. Some studs are designed for thinner metals. Others work on heavy plate steel. Some need special coatings for corrosion resistance. The right specification depends on what you’re fastening and what environment it faces.

Construction Industry Applications

Concrete Deck Anchoring

Construction relies on CD weld studs for permanent fastening solutions. In concrete construction, studs get welded to the steel deck before the concrete pours. This creates anchors for hanging loads, installing equipment, or securing additional structural elements. The studs hold indefinitely because they’re actually part of the steel structure now.

Metal Stud Framing

Metal stud framing uses CD stud welding to attach studs to tracks and plates. Speed matters in construction. Time spent welding means fewer hours on the job. CD stud welding is faster than bolting or traditional welding methods. This efficiency compounds across large projects with countless connection points.

Façade and Exterior Systems

Façade systems use studs to attach anchoring devices. Building exteriors need secure connection points. Studs welded directly to the structure provide that security without creating visible fasteners or potential corrosion points. This approach keeps building exteriors clean and protected.

Fire-Rated Assembly Connections

Fire-rated assemblies benefit from CD weld studs. Because the welding creates an actual bond rather than just mechanical fastening, inspectors accept these connections in fire-rated systems. The connection integrity can’t fail because no bolt could loosen.

Structural Projects and Long-Term Performance

Parking structures, bridge components, and tower construction all depend on reliable fastening. CD weld studs deliver that reliability. A stud welded during construction stays secure for decades without maintenance. The permanence matters for critical structures.

Automotive Manufacturing Uses

Engine Block Assembly

The automotive industry has specific demands for fastening. Vehicles experience vibration, temperature changes, and stress from movement. The engine block assembly uses studs for component mounting. Studs welded directly to the engine block stay tight throughout the vehicle’s life. They won’t vibrate loose as a bolted connection might. This reliability is critical to engine longevity.

Chassis and Structural Fabrication

Chassis fabrication relies on stud welding for structural attachment. Manufacturing efficiency matters. Each second saved compounds across thousands of vehicles. CD stud welding reduces assembly time compared to traditional fastening methods. That time savings translates directly to cost savings at scale.

Interior Panel Mounting

Interior panels attach using studs in high-volume manufacturing. The seats, door panels, and dashboard components need a reliable connection. Studs provide that without visible fasteners that might catch on clothing or interfere with the interior finish. The aesthetic advantage matters for customer satisfaction.

Electrical and Ground Connections

Electrical component mounting uses studs for ground connections. These connections must remain stable and corrosion-free. Stainless steel CD weld studs resist oxidation in the harsh underbody environment. Reliable electrical connections keep vehicle systems functioning properly.

Electric Vehicle Battery Systems

Battery system mounting for electric vehicles depends on secure attachment. As electric vehicles become standard, fastening solutions that stay reliable under repeated charge cycles become critical. Stud welding provides that dependability. The high-stress environment of battery systems demands absolute connection integrity.

Manufacturing and Industrial Applications

Heavy Equipment Fabrication

General manufacturing uses CD weld studs across countless applications. Equipment fabrication requires fastening points that won’t fail during operation. Machinery vibrates. It cycles. It stresses fasteners constantly. Studs welded directly to the equipment frame provide permanent, maintenance-free solutions. The durability means the equipment stays operational with minimal downtime for repairs.

Pressure Vessels and Tank Construction

Pressure vessels and tanks use studs for connection points. These applications demand absolute reliability. A fastener failure could cause dangerous leaks. Welded studs eliminate the risk associated with bolted connections. Safety is the primary concern in these critical applications.

Electrical Equipment and Switchgear

Electrical cabinets and switchgear mounting use studs for equipment attachment. The electrical industry has strict codes. Welded connections meet those codes while providing superior reliability compared to bolted alternatives. Code compliance combined with reliability gives operators confidence.

Production Line Flexibility

Production line equipment stays permanently attached using stud welding. Changing line configurations doesn’t require drilling new holes or dealing with damaged threads. Existing studs get repurposed, or new studs get added quickly. The flexibility enables efficient line reconfiguration.

Material Handling and Processing Systems

Conveyor systems, material handling equipment, and processing machinery all rely on secure fastening. Manufacturing environments are harsh. Temperature swings, humidity, chemical exposure, and constant vibration challenge fastening solutions. CD weld studs survive these conditions better than traditional bolts. Long service life reduces replacement and maintenance costs.

Why CD Weld Studs Beat Alternatives?

Material Integrity Advantage

Comparing fastening methods reveals why studs have become standard across industries. Traditional bolting requires pre-drilled holes. This creates weak points in the material. The hole itself reduces material strength. CD weld studs avoid this weakness entirely. The material stays intact. The stud bonds to solid metal.

Time and Labor Savings

Drilling takes time. Pre-positioning holes requires precision. If holes misalign, you’ve wasted materials and time. Stud welding eliminates these steps. Position the stud. Apply power. You’re done. Labor costs drop significantly across large projects.

Permanent Connection Security

Bolted connections can loosen under vibration. It happens in manufacturing all the time. Maintenance teams spend countless hours retightening bolts. Welded studs never loosen. They’re permanent. The elimination of maintenance saves money over the equipment’s lifetime.

Heat Efficiency Compared to Traditional Welding

Traditional welding creates large heat-affected zones. It weakens the surrounding material. It requires cleanup and finishing work. CD stud welding creates minimal heat damage. The process is clean and finished immediately. Surface finishes and nearby components stay protected.

Cost Analysis Over Equipment Lifetime

Cost comparison favors CD weld studs when you factor in labor. Yes, the equipment costs more upfront. But speed and reliability create savings that quickly offset that investment. Many companies see payback within one to three years.

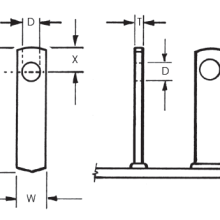

CD Weld Stud Specifications

Material Composition Options

Different applications need different studs. Material composition matters. Carbon steel studs work for most applications. Stainless steel CD weld studs resist corrosion better. Some industries demand stainless steel for durability. Others use carbon steel for cost savings.

Size and Dimensional Standards

Stud diameter and length depend on what you’re fastening. A small electrical panel might use 3/16 inch studs. Heavy structural work might need 1/2 inch studs. Complete Stud Welding stocks sizes for every application. Having the right size matters for proper load distribution.

Thread Configuration Variations

Thread specifications vary. Some studs come fully threaded. Others have smooth shanks with only a threaded tip. The application determines which you need. Through-bolt applications need different configurations than studs designed for component mounting.

Surface Treatments and Coatings

Surface finish affects corrosion resistance and aesthetics. Plain studs work for internal applications. Plated studs resist rust better. Some applications require special coatings for specific environments. Choosing the right finish prevents corrosion and extends stud life.

Engineering for Performance

CD weld stud specifications aren’t guesswork. They’re engineered for specific loads and environments. Using the right specification ensures your connection performs as intended. Under sizing or oversizing creates problems that proper specification selection prevents.

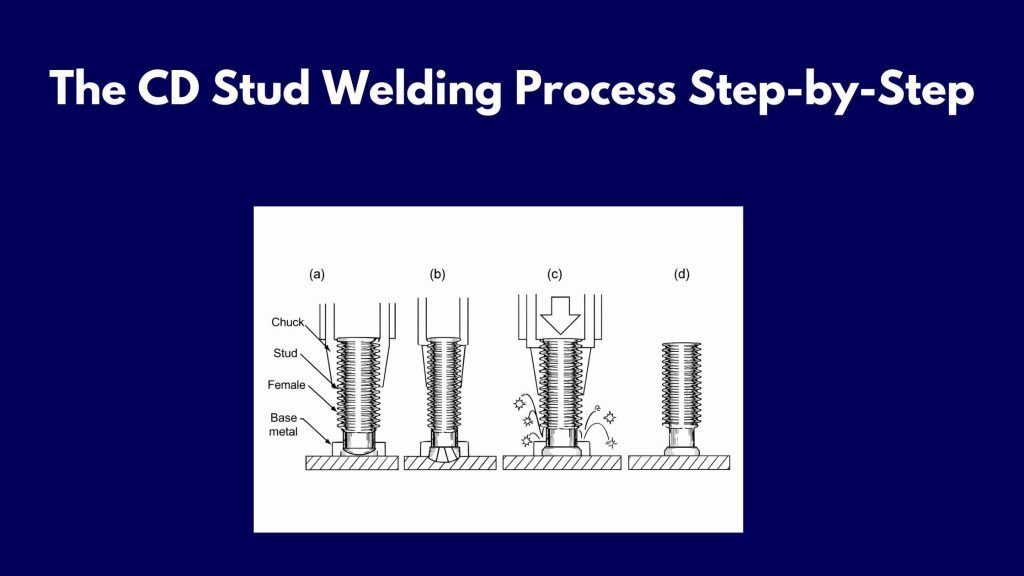

The CD Stud Welding Process Step-by-Step

Surface Preparation Requirements

Understanding the process helps you appreciate why it works so well. Step one is surface preparation. The metal surface needs to be clean. Not sterile, clean, but reasonably free from heavy rust or dirt. A quick wire brush removes most contaminants. The stud welder’s contact point cleans the surface further.

Stud Positioning and Alignment

Step two is positioning. You hold or clamp the stud perpendicular to the surface. Angle matters. A stud at an angle won’t bond properly. You need that perpendicular contact for good results. Fixtures help ensure consistent positioning across multiple studs.

Capacitor Charging Phase

Step three is charging. The CD stud welder charges the capacitor. This takes seconds. The electrical charge builds to a specific level determined by the stud size and base metal thickness. Modern equipment controls this charging precisely.

Electrical Discharge and Fusion

Step four is discharge and fusion. You trigger the release. Electrical current flows. Heat develops at the contact point. Base metal melts. The stud sinks into the molten pool. The molten material flows around the stud base, creating a complete bond.

Cooling and Bond Completion

Step five is cooling. Within seconds, the connection solidifies. The electrical current stops. Heat dissipates. The bond becomes permanent. The speed of cooling helps create strong, reliable welds. The entire process from positioning to finished stud takes less than one second. That speed translates to efficiency on the job.

Contact Us For Your Welding Needs

If you are ready to improve your manufacturing process, reach out to our experts. We can provide the specific CD weld studs and equipment you need to get the job right the first time.

Explore our products: CD Weld Studs Category.

Comments are closed.