Stud welding is a foundational fastening technology across industries like automotive, construction, and shipbuilding. It’s the process of instantaneously welding a metal stud (or fastener) onto another metal workpiece using an electric arc, without needing access to the reverse side. To meet the demands of modern, high-volume manufacturing, this process has evolved into Stud Welding Automation.

Automated Stud Welding is the integration of stud welding equipment with automated systems, such as robotic arms, CNC stud welding automation (Computer Numerical Control) machines, or fixed automation systems, to perform the welding sequence with minimal or no human intervention. This transformation from manual to automated processes is key to achieving unmatched speed, accuracy, and consistency in metal joining.

Key Components of an Automated System

A typical automated stud welding cell combines several sophisticated components to ensure a flawless and efficient process:

- Industrial Robot or CNC Machine

This is the core of automated fastener welding. It precisely positions the stud welding gun at pre-programmed locations on the workpiece. Multi-axis robotic arms offer superior flexibility for complex 3D components, while CNC stud welding automation benches are ideal for high-speed, repetitive flat-surface tasks.

- Automatic Stud Feeder

This system (often a vibratory bowl feeder) automatically orients and delivers the weld studs to the welding gun’s chuck, eliminating the time-consuming manual loading step. This is crucial for maximizing throughput.

- Weld Controller and Power Source

A dedicated, programmable control unit manages the welding parameters (current, time, lift distance, and plunge speed) for each weld. Modern digital controllers allow for precise tuning and data reporting to ensure quality and traceability.

- Specialized Weld Head/Gun

Designed for fixture mounting or robotic integration, these guns perform the actual weld cycle with high repeatability.

The Mechanical Architecture of Automation

A successful automated stud welding cell is a complex convergence of mechanical, electrical, and control systems, designed for zero-defect operation:

1. Motion and Positioning System

The core mechanical driver is typically an industrial robot (offering 6 or more degrees of freedom) or a high-speed Cartesian gantry/CNC system.

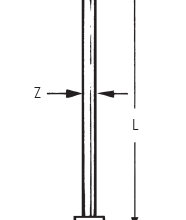

- Function: To position the stud welding head with high dynamic accuracy. Positional repeatability in these systems is critical, often specified down to ± 0.05 mm to ensure the stud lands precisely within the weld zone tolerance.

- Key Consideration: The robot payload must accommodate the weld gun, cables, and often a cooling system, while maintaining maximum acceleration and deceleration for minimum cycle time.

2. High-Speed Stud Feeding and Delivery

The efficiency bottleneck in manual welding is stud loading. Automated fastener welding relies on sophisticated feeding mechanisms:

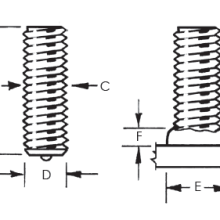

- Vibratory Bowl Feeder: Orients bulk studs (e.g., $M6$ or $M8$ studs) correctly.

- Linear Feed Track: Transports the oriented studs to the delivery system.

- Pneumatic/Vacuum Delivery: A controlled air blast or vacuum pulls the stud rapidly into the chuck of the welding gun, ready for the next cycle. This minimizes the index time between welds.

3. Automated Weld Gun and Tooling

The automated weld head is engineered for durability and integration:

- Fixed Mount Design: Unlike handheld guns, automated guns are designed to be rigidly mounted to the robot flange or gantry.

- Chuck Lifespan: Tooling, especially the chuck and legs, must withstand continuous high-heat cycling while maintaining precise geometry and electrical conductivity. Automated Tool Changers may be incorporated to swap guns for different stud types or sizes without human intervention.

How Robotic Stud Welding Works?

The automated process is completed in milliseconds, ensuring a high-quality, permanent fusion weld:

- Preparation: The workpiece surface and studs are prepared for optimal conductivity. The automatic feeder loads the next stud into the gun.

- Positioning: The robotic arm or CNC stud welding automation moves the weld head to the exact, programmed location on the workpiece.

- Arc Ignition: The weld controller initiates the cycle. A controlled electric arc is drawn between the stud and the workpiece, rapidly melting the end of the stud and a corresponding area on the base metal.

- Joining & Plunge: After the materials reach a molten state, the system plunges the stud into the molten pool. The molten metal solidifies almost instantly, creating a high-strength, full-fusion bond.

- Cycle Completion: The robotic stud welding moves on to the next weld location.

Benefits Of Stud Welding Automation Technology

Integrating stud welding automation offers manufacturers significant competitive advantages:

- Superior Quality and Repeatability

Welding automation technology eliminates human error and fatigue. Every weld is executed with the exact, programmed parameters, ensuring uniform weld penetration and precise stud placement—a necessity for critical applications like aerospace and automotive assembly.

- Increased Productivity and Speed

Welding automation technology systems can operate 24/7 without breaks, significantly reducing the cycle time per stud. This leads to dramatically higher throughput compared to manual methods, boosting overall manufacturing efficiency.

- Reduced Labor Costs and Safety

While requiring an initial investment, the long-term benefit is a reduced need for manual welding labor. Furthermore, automated high-productivity welding removes human operators from the hazardous direct welding environment, improving workplace safety.

- Weld Data and Quality Control

Programmable controls offer advanced data reporting capabilities, allowing for the logging of parameters (current, time) for every single weld. This provides essential documentation for quality assurance and regulatory compliance.

Applications Across Industries

The versatility of automated stud welding makes it invaluable in numerous sectors, utilizing both Capacitor Discharge (CD) Stud Welding for thin metals and Drawn Arc Stud Welding for thicker, structural materials:

| Industry | Common Applications | Key Benefit |

| Automotive | Attaching wire hangers, heat shields, brackets, and interior components to car bodies. | Speed and precision on high-volume assembly lines. |

| Construction | Welding shear connectors to steel beams for composite concrete decking. | High strength and structural integrity on heavy materials. |

| Appliances/HVAC | Fastening internal components to thin sheet metal panels (refrigerator bodies, oven hoods). | Minimal heat, preventing burn-through and reverse-side marking. |

| Shipbuilding | Securing insulation, conduit, and wiring to bulkheads and decks. | Durability, consistency, and single-sided access. |

Manual Stud Welding vs. Automated Stud Welding

Workflow Differences

Manual welding depends on the skill of the operator. Automated welding follows a programmed sequence, ensuring repeatable results.

Cost and ROI Comparison

Automated weld monitoring systems require upfront investment, but most companies recover the cost quickly through labor savings and reduced rework.

The Future of Fastening is Automated

Stud welding automation is more than just a technological upgrade; it’s a strategic investment that future-proofs manufacturing operations. By combining the proven strength of stud welding with the speed and precision of robotics and CNC control, manufacturers can achieve unprecedented levels of quality, efficiency, and safety.

If your production demands high volume, tight tolerances, and consistent quality, an automated stud welding system is the definitive path forward.

Ready to discuss how integrating robotic stud welding can transform your manufacturing line? Visit our website, Complete Stud Welding, or contact our experts at 216 904-4008 today!

Comments are closed.