The automotive industry demands fastening solutions that combine speed, strength, and precision. Stud welding is a highly valued and indispensable technique within the automotive industry, enabling secure attachment of flanges, brackets, lighting fixtures, and other critical components to vehicle bodies and frames.

Among the most reliable fastening methods available, metric weld studs offer a standardized and efficient way to join metal components to sheet metal and structural frames without requiring drilling or threading on the assembly side.

This comprehensive guide explores everything you need to know about metric weld studs in automotive manufacturing—from understanding ISO standards and material specifications to implementing best practices that prevent costly failures and rework.

What Are Metric Weld Studs?

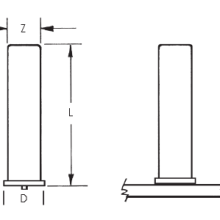

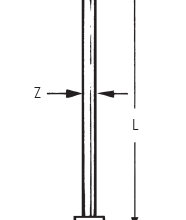

A metric weld stud is a threaded metal fastener, manufactured to metric dimensions (M3–M12+), specifically designed to be welded to a base metal component through stud welding. Unlike traditional drilled-and-tapped fasteners, such as bolts or screws, which require pre-drilled holes or threads on both sides, metric weld studs are attached via a welding process that creates a permanent, high-strength bond between the stud and the substrate.

Common automotive variants include:

- Metric stainless steel weld studs for corrosion resistance

- Metric projection weld studs for thin sheet metal

- Carbon steel weld studs for structural components

Weld studs allow for the joining of externally threaded fasteners to another metal part. The stud provides the threaded portion for accepting nuts or other fasteners on the accessible side, while the weld base anchors the entire assembly to the workpiece.

How Metric Weld Studs Function in Automotive?

The metric weld stud operates through a straightforward principle: electrical energy melts both the base of the stud and the surface of the workpiece, creating a molten pool that fuses the two materials together. The stud remains stationary relative to the base metal after cooling, creating a joint that can withstand significant mechanical loads.

In automotive applications, this means:

- No need to access both sides of the substrate

- Elimination of drilling operations that weaken the parent material

- Single-sided installation without marring the opposite surface

- Minimal heat distortion compared to traditional welding methods

- Consistent, repeatable joints suitable for high-volume production

The Role of Metric Weld Studs in the Automotive Industry

The automotive industry has embraced metric weld studs and stud welding technology for sound engineering reasons. In the automotive industry, the process is used to assemble heat shields, power steering and dashboard components, instrument panels, insulation, exhaust systems, lighting systems, brake lines, trim, and electrical wire routing.

Speed and Production Efficiency

Stud welding is measured in milliseconds, making it the best way to join fasteners and other types of studs to sheet metal in large-scale production. A single metric weld stud can be installed in as little as 50 milliseconds to 1.5 seconds, depending on the welding method. This speed advantage compounds across thousands of vehicles, translating directly into reduced manufacturing costs and faster assembly line throughput.

Structural Integrity and Load-Bearing Capacity

Unlike mechanical fasteners that rely on clamp force, a welded stud joint achieves metallurgical fusion. The roofing and insulation industry relies on stud welding to attach fasteners to the metal substrate, with the capacitor discharge stud welders attaching them to the metal substrate quickly and efficiently. When properly executed, the weld creates a joint that equals or exceeds the strength of the stud material itself.

Aesthetic and Functional Advantages

Neat, clean, and low-profile welds make them ideal for automotive applications where aesthetics and aerodynamics are important. Metric stainless steel weld studs, in particular, eliminate the need for painted brackets or unsightly bolt heads, improving both the visual appeal and corrosion resistance of vehicle assemblies.

Key Considerations for Choosing Weld Studs

The shift toward “Lightweighting” in automotive design means that base materials are thinner than ever. Selecting the wrong metric weld studs or using an uncalibrated stud welder can lead to several catastrophic failures:

- Burn-through: Damaging the aesthetic or structural integrity of thin-gauge sheet metal.

- Cold Welds: A weak bond that may pass initial inspection but fails under the vibration and thermal stress of real-world driving.

- Corrosion Acceleration: Using mismatched materials (galvanic corrosion) can lead to premature rusting at the joint.

ISO 13918 Standard for Metric Weld Studs

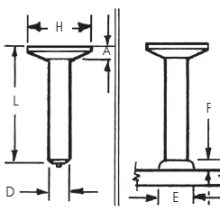

ISO 13918 formerly referred to the DIN 32501 specification. This international standard establishes the dimensions, materials, mechanical properties, and quality requirements for metric weld studs used across diverse industries, including automotive manufacturing.

| Standard Element | Details |

| Stud Diameters | Metric sizes from M2 to M8 (and larger) |

| Stud Lengths | Lengths up to 60mm, with variations for specific applications |

| Material Options | Carbon steel (various strength classes), stainless steel (A2, A4, A5), and aluminum alloys |

| Threading | External threads conforming to metric thread standards |

| Weld Base Geometry | Standardized projection or flat-bottomed designs for specific welding methods |

| Mechanical Properties | Tensile strength, yield strength, and elongation specifications |

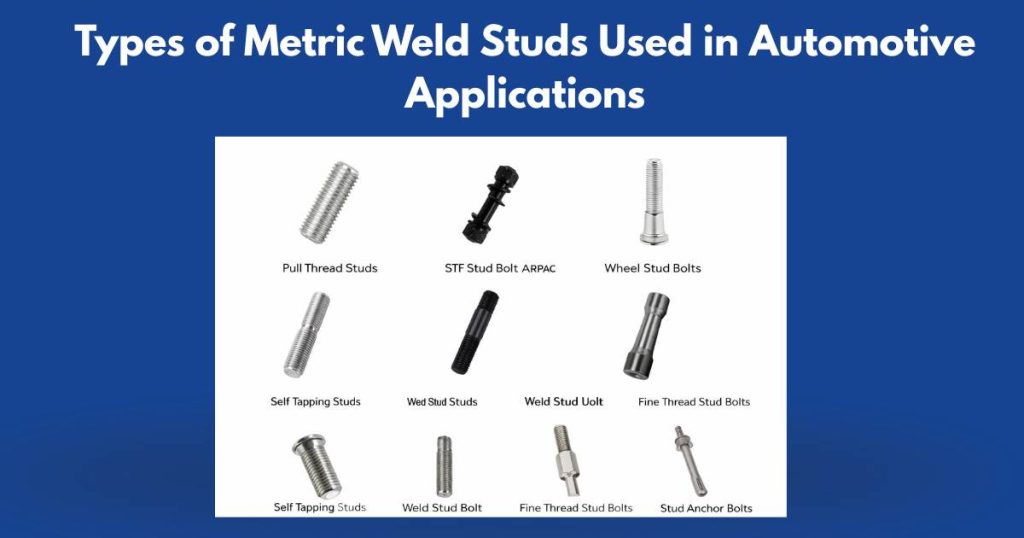

Types of Metric Weld Studs Used in Automotive Applications

Automotive manufacturers choose from several configurations of metric weld studs, each optimized for different welding processes and application requirements.

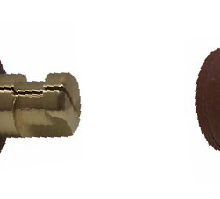

Tip-Ignition Projection Weld Studs (Type PT)

Metric projection weld studs feature small raised projections on the bottom surface that concentrate electrical current during the welding process. These studs are ideal for capacitor discharge (CD) welding, where precise, localized energy delivery matters.

Advantages for automotive use:

- Fast weld cycles (2-12 milliseconds typical).

- Minimal heat input reduces substrate distortion.

- Excellent cosmetic appearance on both sides.

- Ideal for thin sheet metal and visible surfaces.

Common applications: Trim pieces, door panels, interior trim, visible fastening points

Drawn Arc Studs (Type DA)

Drawn arc studs are designed for longer weld cycles and higher heat input. An electric arc forms between the stud and base metal, melting both surfaces before they’re forced together.

Advantages for automotive applications:

- Suitable for thicker base materials

- Greater penetration depth (up to 0.125 inch)

- Tolerant of slightly contaminated or coated surfaces

- Higher tensile strength welds

Common applications: Heat shields, structural reinforcements, load-bearing brackets, powertrain components

Shear Connectors and Internal Thread Studs

Beyond traditional metric weld studs with external threads, the ISO 13918 standard covers specialized variations, including studs with internal threads (tapped studs) and connectors designed for specific shear applications in structural assemblies.

Best Practices for Installing Metric Weld Studs

To ensure your assembly meets the rigorous standards set by organizations like the International Organization for Standardization (ISO 13918), follow these expert-vetted best practices:

1. Match the Material Grade

Always match the metallurgy of your metric stainless steel weld studs to the base material whenever possible. If welding to aluminum or high-strength steel, ensure your weld studs are specifically rated for those alloys.

2. Verify Equipment Calibration

Stud welding equipment should undergo daily calibration checks. Variations in voltage or spring pressure can result in inconsistent penetration.

3. Use the Correct Shielding Gas

For larger diameter weld studs (typically over 10mm), using a shielding gas like Argon-CO2 can prevent porosity in the weld pool, ensuring a “leak-proof” seal.

| Feature | CD Welding | Drawn Arc Welding |

| Material Thickness | Best for thin sheets (<2mm) | Best for thicker plates (>2mm) |

| Weld Time | 1–3 milliseconds | 100–1000 milliseconds |

| Aesthetic | Minimal reverse-side marking | Visible weld fillet |

Summing Up

Metric weld studs represent a proven, standardized fastening solution for automotive manufacturers seeking to combine speed, strength, and precision. Stud welding’s ability to create strong and long-lasting connections while eliminating the need for additional fasteners or intrusive welding methods makes it a winning process in automotive manufacturing.

If you’re working on an automotive assembly project and need specialized expertise on metric weld studs, fastening standards, or stud welding equipment selection, the team at Complete Stud Welding can help guide you through the technical details and practical implementation challenges.

Call us at 216-904-4008 to explore how optimized fastening solutions can improve your production efficiency and product quality.

Comments are closed.